◆ Introduction

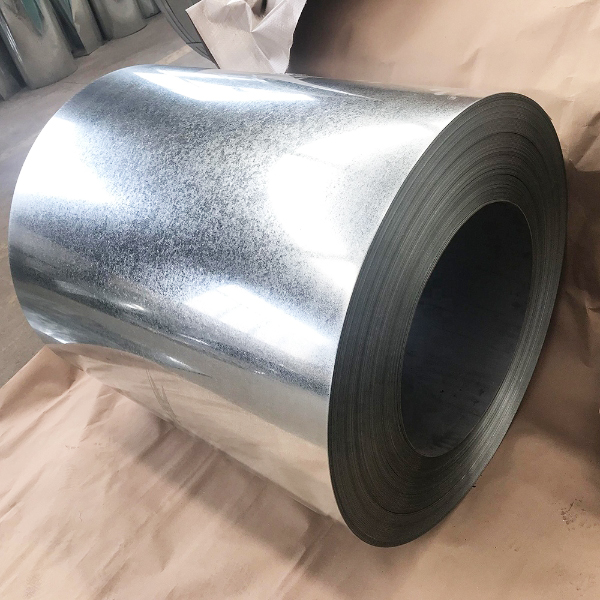

The surface of the galvalume steel coil has a unique smooth, flat and gorgeous star flower, and the base color is silvery white. The special coating structure makes it have excellent corrosion resistance. The galvalume steel coil has good heat resistance and can be used in a high temperature environment of 315°C; the coating of the cold rolled steel coil has good adhesion to the paint film, and has good processing performance, and can be stamped, cut, welded, etc.; The surface of coil rolled galvalume steel coil is very conductive.

The coating composition of cold rolled steel coil consists of 55% aluminum, 43.4% zinc and 1.6% silicon by weight. The production process of galvalume steel coils is similar to that of galvanized steel coils and aluminum-coated coils, both of which are continuous melting plating processes. Compared with galvanized steel coils of the same thickness, 55% galvalume-coated galvalume steel coils have superior corrosion resistance when both sides are exposed to the same environment. The 55% aluminum-zinc alloy coated galvalume steel coil not only has good corrosion resistance, but also color-coated products have excellent adhesion and flexibility.

◆ Galvanized Steel Coil Types

According to the processing method, we divide galvanized steel into the following categories:

1.Hot-dip Galvanized Steel Coil

As the name implies, hot-dip galvanizing

is immersing the cleaned iron sheet into the molten zinc bath at about

500 degrees to form a zinc layer. It is the most commonly used method.

It has some advantageous features:

1) The entire steel surface is uniformly

covered with a zinc layer, even the corners, hollows, etc. so that the

steel sheet is fully protected.

2) The cost of hot-dip galvanizing is cheap.

2. Electro-galvanized Steel Coil

Electro-galvanizing is a process of

applying a layer of zinc to steel through electroplating, with a saline

anode and steel conductor. It is able to enhance the corrosion and heat

resistance of steel. Also, it makes steel sheets more good-looking.

◆ Applications

Galvalume steel coil's unique protective characteristics and economical price point make it ideal for:

Construction: roofs, walls, garages, sound insulation walls, pipes and prefabricated houses, etc.;

Automobile: mufflers, exhaust pipes, wiper accessories, fuel tanks, truck boxes, etc.;

Home appliances: refrigerator back panel, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electrical cabinet, etc.;

Agricultural use: Pig houses, chicken houses, granaries, greenhouse pipes, etc.;

Others: heat insulation cover, heat exchanger, dryer, water heater, etc.

◆ Purchasing Information

Product Name | Cold Rolled AluZinc Galvalume Steel Coil

|

|

Origin |

China |

|

Certificate |

ISO9001, ISO14001, OHSAS18001 |

|

Technique |

cold rolled

|

Type

| cold rolled steel coil

|

|

Thickness |

0.12mm-2.0mm |

|

Width |

30mm-1500mm |

|

Tolerance |

thickness±0.01mm |

|

T Bending(top/back) |

≤ 3T/4T |

| Packaging | Standard packing for sea, air or rail transport |

| Delivery | 10-15 working days after the receipt of 30% deposit |

| Regular Order | 25 tons or one container,for less quantity,to contact with us for details |

| Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc |

*If you do not find what you are

looking for, please call us now. If you have found it, we are happy to

answer any questions or concerns you may have about stainless steel

grades and assist you through the purchasing process.

|

◆ Order Process

The order process of our Hanhuang Metal galvalume steel coil products:

Receive Inquiry(drawing,temper,etc.)

Feasibility study & quotation

Offer is accepted by customer

Comfirmation on order details

Signing Pl

Receive deposit

Design&make the die for extrusion

Mold test,make samples

Sample approval,mass production

Receive balance

Deiivery

◆ FAQ:

Q:Can you send samples?

A:Sample can be for free,freight cost collect.

Q:What product information do I need to provide?

A:Steel grade/thickness/width/quantity,these will decide the price.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:What are the certifications for your products?

A:We have ISO 9001,CE,SGS,BV and other certifications.

Q:How about the delivery time?

A:Regularly the delivery time around 10-15 days,customized one will inform the delivery time ahead.

Q:Does the product have quality inspection before loading?

A:All the products are strictly tested before packaging,also can inspect by third party inspection.

Q:How to pack the products?

A:Standard export package with waterproof film and wooden pallet.It can effectively protect products from corrosion.

Leave a Comment