Galvanized sheet and cold rolled sheet galvanized

introduction

Abstract

The aim of this article is to provide an in-depth understanding of galvanized sheet and cold rolled sheet galvanized. This introduction will pique readers' interest and provide necessary background information.

Text

1. Introduction

1.1 Galvanized Sheet: A Versatile Material

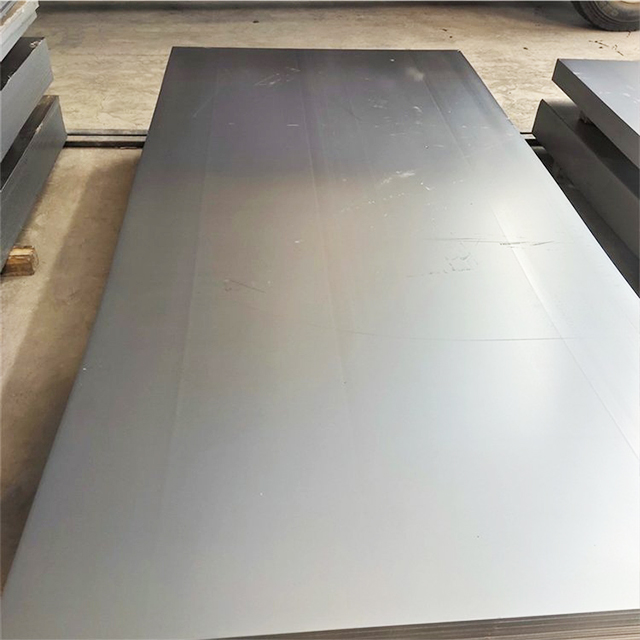

Galvanized sheet, also known as galvanized steel, is a popular material in various industries due to its exceptional corrosion resistance and durability. It is obtained by coating a layer of zinc on the surface of the steel sheet through a process known as galvanization. This protective zinc layer not only prevents corrosion but also enhances the overall strength of the sheet. Galvanized sheets find wide applications in construction, automotive, and appliances sectors.

1.2 Cold Rolled Sheet  Galvanized: Enhanced Properties

Galvanized: Enhanced Properties

Cold rolled sheet galvanized is a specialized form of galvanized sheet produced through additional processing steps. Cold rolling is a technique that involves passing the steel sheet through rollers at room temperature. This process improves the surface finish, thickness uniformity, and mechanical properties of the galvanized sheet. Cold rolled sheet galvanized offers superior strength and dimensional accuracy, making it suitable for critical applications such as automotive body panels and industrial components.

1.3 Growing Demand and Market Trends

The galvanized sheet and cold rolled sheet galvanized market have experienced significant growth in recent years. Factors such as urbanization, infrastructure development, and industrialization have fueled the demand for these materials. Additionally, advancements in coating technologies and the introduction of environmentally friendly galvanized coatings have further expanded their applications. Understanding the market trends is crucial for manufacturers and consumers to make informed decisions.

2. Galvanization Process

2.1 Hot-dip Galvanizing: A Robust Coating Method

Hot-dip galvanizing is the most widely used method for galvanizing sheets. It involves immersing the steel sheet into a molten zinc bath, which forms a metallurgical bond with the steel surface. This process creates a thick and durable zinc layer that provides excellent corrosion resistance. The hot-dip galvanizing process involves several steps, including surface preparation, fluxing, dipping into the zinc bath, and post-treatment.

2.2 Electro-galvanizing: Precision Coating for Thin Sheets

Electro-galvanizing is a process that applies a thin layer of zinc onto the steel sheet through an electrolytic deposition process. This technique is commonly used for galvanizing thin sheets where precise control of coating thickness is required. Electro-galvanized sheets offer excellent surface aesthetics and are often used in the production of appliances and decorative products.

2.3 Differences between Hot-dip and Electro-galvanizing

While both hot-dip and electro-galvanizing offer corrosion protection, they differ in terms of coating thickness, coating uniformity, and mechanical properties. Hot-dip galvanizing provides a thicker and more robust coating, making it suitable for heavy-duty applications. Electro-galvanizing, on the other hand, offers a smoother and thinner coating, making it ideal for applications requiring precise dimensions and a smooth surface finish.

3. Advantages and Applications

3.1 Corrosion Resistance and Durability

One of the major advantages of galvanized sheet and cold rolled sheet galvanized is their exceptional resistance to corrosion. The zinc coating acts as a barrier, preventing moisture and corrosive elements from reaching the steel surface. This protective layer extends the lifespan of the sheet, making it a preferred choice for outdoor and harsh environmental conditions.

3.2 Strength and Formability

Galvanized sheet and cold rolled sheet galvanized possess excellent mechanical properties, including high tensile strength and formability. These sheets can be easily formed and fabricated, allowing manufacturers to create complex shapes and structures without sacrificing strength. Such versatility makes them suitable for diverse applications, such as roofing, siding, and structural components.

3.3 Applications in Various Industries

The unique properties of galvanized sheet and cold rolled sheet galvanized make them indispensable in various industries. In construction, these sheets are used for roofing, wall cladding, and framing. The automotive industry relies on galvanized sheets for body panels, chassis components, and structural reinforcements. Additionally, appliances, electrical enclosures, and furniture are among the numerous sectors that benefit from the corrosion resistance and aesthetic appeal of galvanized sheets.

4. Conclusion

In conclusion, galvanized sheet and cold rolled sheet galvanized offer unparalleled corrosion resistance, durability, and strength. The galvanization process, whether through hot-dip or electro-galvanizing, provides a protective zinc coating that enhances the performance and longevity of the sheets. Their wide range of applications across industries is a testament to their versatility and reliability. As the market continues to evolve, it is crucial for manufacturers and consumers to stay updated with the latest advancements in galvanized sheet technology and explore innovative uses to meet the ever-growing demands.

Leave a Comment