PPR pipe and galvanized pipe parameters

introduction

Abstract:

This article explores the parameters of PPR pipe and galvanized pipe, providing readers with a comprehensive understanding of these two types of pipes. The aim is to educate readers about the differences, advantages, and applications of PPR pipe and galvanized pipe in various industries. By delving into the technical specifications, durability, and performance of these pipes, readers will gain valuable insights into their characteristics and suitability for different plumbing needs.

Text:

1. Technical Specifications

PPR Pipe Parameters:

PPR pipe stands for Polypropylene Random Copolymer pipe, and it has become increasingly popular in plumbing systems due to its excellent heat resistance, corrosion resistance, and durability. The technical specifications of PPR pipe include its diameter, wall thickness, pressure rating, and service life.

Diameter: PPR pipes are available in various diameters, including 20mm, 25mm, 32mm, and 40mm. The choice of diameter depends on the specific plumbing application and the flow rate required.

Wall Thickness: The wall thickness of PPR pipes determines their strength and durability. Generally, PPR pipes have different wall thickness options, such as 2.0mm, 2.3mm, and 3.0mm, allowing for versatile use in both residential and commercial settings.

Pressure Rating: The pressure rating of PPR pipes refers to their ability to withstand internal pressure. Common pressure ratings for PPR pipes are 1.6MPa, 2.0MPa, and 2.5MPa. It is essential to select a pipe with an appropriate pressure rating to ensure the integrity of the plumbing system under different operating conditions.

Service Life: PPR pipes have excellent longevity, typically ranging from 50 to 100 years. This long service life makes them highly desirable for both new installations and pipe replacements. However, factors such as water quality and installation practices can influence the actual lifespan of PPR pipes.

Galvanized Pipe Parameters:

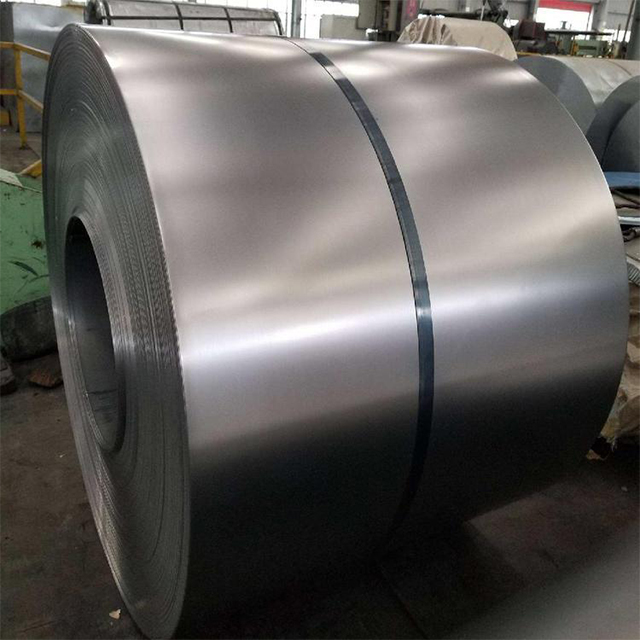

Galvanized pipes, on the other hand, are made of steel and coated with a layer of zinc to prevent corrosion. The technical specifications of galvanized pipes include their diameter, wall thickness, and zinc coating thickness.

Diameter: Galvanized pipes are available in various diameters, ranging from 1/2 inch to 6 inches. The choice of diameter depends on the intended use, such as residential plumbing, irrigation systems, or industrial applications.

Wall Thickness: The wall thickness of galvanized pipes affects their strength and resistance to pressure. It can be specified as different schedules, such as Schedule 40, Schedule 80, and Schedule 160, where higher numbers indicate thicker walls.

Zinc Coating Thickness: The thickness of the zinc coating on galvanized pipes is crucial for corrosion protection. It is measured in ounces per square foot (oz/ft^2) or grams per square meter (g/m^2). Common zinc coating thicknesses for galvanized pipes are G60 and G90, with G90 being thicker and providing better protection against corrosion.

2. Durability

PPR Pipe Durability:

One of the notable advantages of PPR pipes is their exceptional durability. They are highly resistant to chemical attacks, such as acidity or alkalinity in water, making them suitable for a wide range of applications, including hot and cold water plumbing systems, HVAC systems, and industrial pipelines. Additionally, PPR pipes exhibit excellent resistance to impact and abrasion, reducing the likelihood of cracks or leaks even in high-stress environments.

Galvanized Pipe Durability:

Galvanized pipes are renowned for their durability in outdoor and corrosive environments. The zinc coating acts as a barrier between the  steel and the surrounding elements, protecting the pipe from rust and corrosion caused by moisture, chemicals, and atmospheric exposure. This durability makes galvanized pipes ideal for applications such as irrigation, gas pipelines, and outdoor plumbing systems.

steel and the surrounding elements, protecting the pipe from rust and corrosion caused by moisture, chemicals, and atmospheric exposure. This durability makes galvanized pipes ideal for applications such as irrigation, gas pipelines, and outdoor plumbing systems.

3. Performance

PPR Pipe Performance:

PPR pipes offer excellent thermal insulation properties, making them suitable for hot water plumbing systems. They have low thermal conductivity, effectively retaining heat and minimizing heat loss during water transport. Moreover, PPR pipes have smooth interior surfaces that prevent scaling and fouling, maintaining a smooth flow of water and reducing the risk of clogs or blockages. Additionally, PPR pipes have a low coefficient of friction, resulting in lower pressure drops and energy savings in long-distance plumbing installations.

Galvanized Pipe Performance:

Galvanized pipes exhibit good mechanical properties, making them suitable for high-pressure and industrial applications. They have high tensile strength and excellent bending and impacting resistance, ensuring their performance in dynamic installations. Galvanized pipes also have moderate thermal conductivity, making them suitable for both hot and cold water plumbing systems. However, the presence of the zinc coating can cause a slight restriction in water flow, which should be considered in systems with specific flow rate requirements.

4. Applications

PPR Pipe Applications:

PPR pipes find extensive use in residential, commercial, and industrial plumbing systems. Due to their excellent resistance to chemicals and high temperatures, they are commonly used for hot and cold water supply, radiant floor heating, and compressed air systems. PPR pipes also find application in industries that require the transportation of corrosive fluids or gases.

Galvanized Pipe Applications:

Galvanized pipes are widely used in outdoor plumbing systems, such as water supply lines for gardens, sprinkler systems, and wastewater drainage. Additionally, they find application in gas pipelines, fire sprinkler systems, and some industrial processes that require corrosion-resistant pipes. The durability and affordability of galvanized pipes make them a popular choice for various applications.

Conclusion:

To summarize, the parameters of PPR pipe and galvanized pipe play a crucial role in determining their suitability for different plumbing applications. Understanding the technical specifications, durability, performance, and applications of these pipes is vital for making informed decisions in plumbing installations. Whether it is the heat resistance and chemical durability of PPR pipes or the corrosion resistance and affordability of galvanized pipes, each type offers unique advantages that can be tailored to specific needs. By considering the parameters discussed in this article, individuals and businesses can select the most appropriate pipe for their plumbing requirements. Continued research and technological advancements in pipe materials and manufacturing processes will further enhance the performance and utility of both PPR pipe and galvanized pipe in the future.

Leave a Comment