How to calculate the thickness of galvanized sheet

introduction

How to Calculate the Thickness of Galvanized Sheet

Abstract:

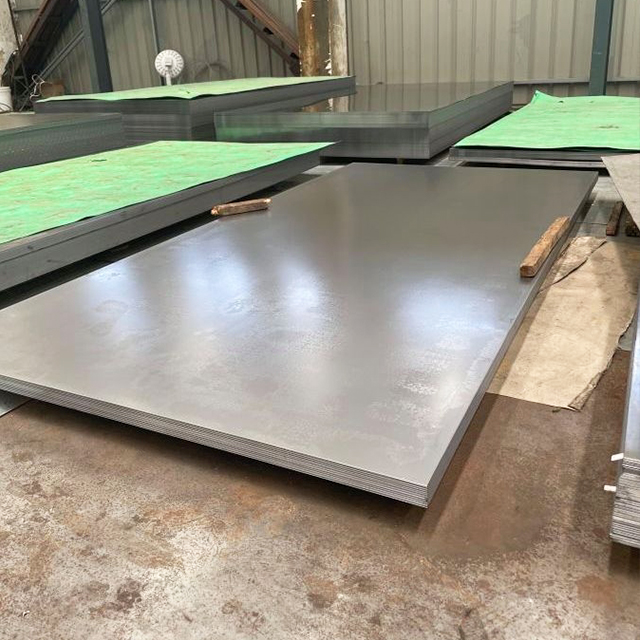

This article aims to provide a comprehensive guide on how to calculate the thickness of galvanized sheet. Galvanized sheet is commonly used in various industries due to its corrosion-resistant properties. Understanding the thickness of galvanized sheet is crucial for ensuring its structural integrity and suitability for specific applications. This article will discuss the calculation methods and factors that influence the determination of galvanized sheet thickness, providing readers with essential information and practical insights.

Text:

1. Factors Affecting Galvanized Sheet Thickness

Galvanized sheet thickness is influenced by several factors that must be taken into account during the calculation process. Firstly, the type and grade of galvanized sheet used play a significant role. Different types of galvanized coatings, such as hot-dip galvanizing and electro-galvanizing, have varying thickness ranges. Moreover, the grade of steel and the coating weight applied can also impact the final sheet thickness. These factors should be carefully analyzed when calculating galvanized sheet thickness.

Additionally, environmental conditions and intended application should be considered. Galvanized sheet used in marine environments or highly corrosive atmospheres may require thicker coatings to provide adequate protection. Similarly, structural applications that require high strength may necessitate thicker galvanized coatings. Understanding these environmental and application-related factors is essential for accurate thickness calculation.

Furthermore, the sheet's intended service life and maintenance requirements should be taken into consideration. Longer service life requirements might call for thicker galvanized coatings to ensure durability and longevity. Conversely, shorter service life needs may allow for thinner coatings, considering maintenance schedules. Proper evaluation of the expected service life and maintenance practices is essential for precise thickness calculation.

2. Methods for Calculating Galvanized Sheet Thickness

Obtaining the correct thickness of galvanized sheet involves employing various calculation methods. One commonly used method is the Weight Method. This method relies on measuring the sheet's weight per unit area and utilizing conversion formulas to determine the corresponding thickness. The Weight Method provides a quick and straightforward estimation, especially when dealing with large-scale galvanized sheet production.

Another method utilized is the Optical Method. By utilizing advanced optical technologies, the thickness of the galvanized coating can be measured accurately. The Optical Method allows for non-contact measurement, making it suitable for quality control and inspection purposes. This method provides precise results and is commonly used in research and development activities.

Additionally, the Magnetic Method is another approach to calculating galvanized sheet thickness. By using magnetic induction principles, this method measures the thickness of the galvanized layer through non-destructive testing. The Magnetic Method is frequently employed in industrial settings due to its non-intrusive nature and ability to measure the coating thickness on assembled structures.

3. Practical Application: Case Studies and Examples

To illustrate the calculation methods discussed, several practical case studies and examples can be examined. These case studies will cover different galvanized sheet applications, various corrosion environments, and differing service life requirements. Through these examples, readers can gain a better understanding of how to apply the calculation methods according to specific scenarios.

In one case study, the galvanized sheet is used in a seaside construction project with an expected service life of 30 years. The calculation method employed should consider factors such as the corrosiveness of the marine environment, the structural requirements, and industry standards for coating thickness. By taking these aspects into account, an accurate thickness calculation can be achieved.

Another case study may involve galvanized sheets used in agricultural environments. The calculation method utilized should consider factors such as exposure to chemicals, fertilizers, and weather conditions. Additionally, the maintenance practices and expected service life of the galvanized sheet in an agricultural setting must be evaluated. Through careful analysis, the appropriate thickness can be determined to ensure the longevity of the coating.

Conclusion:

Calculating the thickness of galvanized sheet is crucial for selecting the right material for specific applications. By considering factors such as type and grade of galvanized coating, environmental conditions, intended service life, and maintenance requirements, accurate thickness calculation can be achieved. Utilizing calculation methods such as the Weight Method, Optical Method, and Magnetic Method  further enhances precision. Through case studies and examples, readers can gain practical insights into applying these calculation methods to real-world scenarios. A thorough understanding of how to calculate the thickness of galvanized sheet enables better decision-making, leading to increased corrosion resistance and improved product performance.

further enhances precision. Through case studies and examples, readers can gain practical insights into applying these calculation methods to real-world scenarios. A thorough understanding of how to calculate the thickness of galvanized sheet enables better decision-making, leading to increased corrosion resistance and improved product performance.

Leave a Comment