How to calculate the net material area of galvanized sheets

introduction

How to Calculate the Net Material Area of Galvanized Sheets

Abstract

This article aims to provide a comprehensive guide on how to calculate the net material area of galvanized sheets. Galvanized sheets are widely used in various industries due to their durability and corrosion-resistant properties. Understanding how to accurately calculate the net material area is essential for cost estimation, material procurement, and project planning. By following the guidelines presented in this article, readers will gain valuable insights into this process and be able to apply it effectively in their respective fields.

1. The Importance of Calculating the Net Material Area

1.1 Introduction to Galvanized Sheets

1.2 The Significance of Calculating Net Material Area

1.3 Background Information on Galvanized Sheet Applications

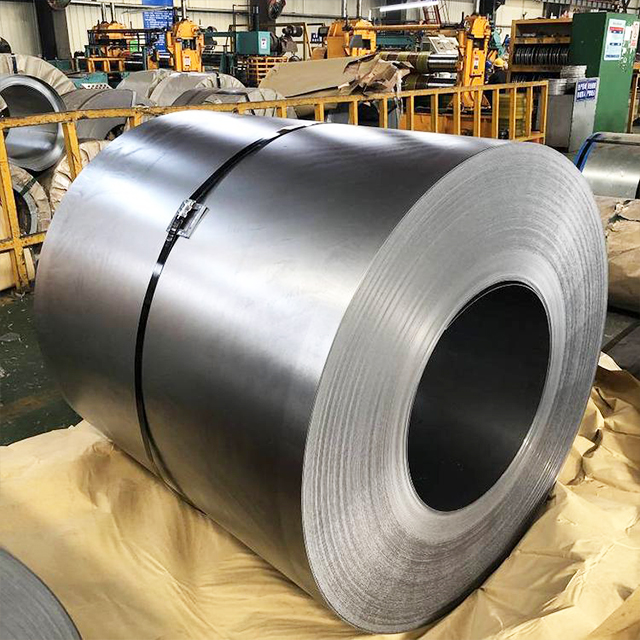

Galvanized sheets, also known as galvanized steel sheets, are steel sheets coated with a layer of zinc to protect them from rust and corrosion. Due to their exceptional strength, durability, and aesthetic appeal, galvanized sheets are extensively used in construction, automotive, and manufacturing industries. As a versatile material, it is vital to calculate the net material area, which refers to the actual usable area of the sheet, for accurate material procurement, cost estimation, and optimizing project efficiency.

2. Factors Affecting Calculation of Net Material Area

2.1 Thickness and Gauge

2.2 Width and Length

2.3 Overlapping and Waste Factors

2.4 Accounting for Special Shapes and Cutouts

2.1 Thickness and Gauge

When calculating the net material area, the thickness and gauge of the galvanized sheet play a crucial role. Thicker sheets have a larger volume, and thus, their net material area will be less compared to thinner sheets of the same dimensions. Manufacturers provide the gauge size, which affects the sheet thickness, and it is important to consider this when calculating the net material area.

2.2 Width and Length

The width and length of the galvanized sheet determine its total surface area. However, when calculating the net material area, it is necessary to account for any excess material that may be present due to manufacturing tolerances. Measuring the actual width and length, and subtracting any overlapping or excess material, will yield the accurate net material area.

2.3 Overlapping and Waste Factors

During the installation of galvanized sheets, overlapping is often required to ensure the sheets are properly secured. Additionally, certain waste factors, such as the cutting width, need to be considered to avoid unnecessary material loss. By accounting for overlapping and waste factors, the calculation of the net material area becomes more precise.

2.4 Accounting for Special Shapes and Cutouts

In some projects, galvanized sheets may require special shapes or cutouts to fit specific design requirements. These irregularities can impact the net material area calculation, as they often produce waste material. It is crucial to measure and factor in these special shapes and cutouts accurately when determining the net material area.

3. Methods of Calculating Net Material Area

3.1 Method 1: Rectangular Sheets

3.2 Method 2: Circular Sheets

3.3 Method 3: Sheets with Irregular Shapes

3.4 Method 4: Sheets with Cutouts

3.1 Method 1: Rectangular Sheets

For rectangular sheets, calculating the net material area involves subtracting the overlapping areas and waste factors from the total surface area. By accurately measuring and accounting for these variables, an accurate net material  area for rectangular galvanized sheets can be obtained.

area for rectangular galvanized sheets can be obtained.

3.2 Method 2: Circular Sheets

For circular sheets, the net material area calculation involves excluding any excess material due to overlapping or waste factors. The radius or diameter of the circular sheet should be measured precisely to ensure an accurate calculation.

3.3 Method 3: Sheets with Irregular Shapes

Calculating the net material area for sheets with irregular shapes requires breaking down the shape into smaller regular shapes, such as triangles or rectangles. By adding up the net material areas of these smaller shapes, an accurate calculation of the total net material area can be achieved.

3.4 Method 4: Sheets with Cutouts

Sheets with cutouts require a more intricate calculation method. The net material area can be determined by subtracting the cutout areas from the total surface area. Precise measurements and consideration of any waste factors involved in the cutout process are vital in obtaining an accurate net material area.

4. Conclusion

In conclusion, accurately calculating the net material area of galvanized sheets is crucial for project planning, cost estimation, and material procurement. By considering factors such as thickness, width, length, overlapping, waste factors, special shapes, and cutouts, professionals can ensure efficient utilization of materials and minimize waste. This article has provided a comprehensive guide on how to calculate the net material area of galvanized sheets, enabling readers to apply this knowledge in their specific industries and projects.

Leave a Comment