Black punched galvanized sheet

introduction

Abstract:

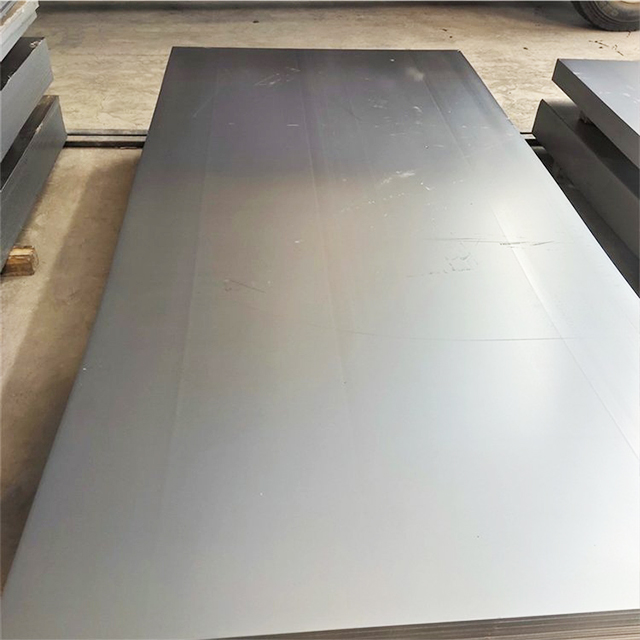

Black punched galvanized sheet is a type of sheet metal that has undergone a galvanizing process and has a black punched surface for added durability and aesthetics. This article aims to provide a comprehensive understanding of black punched galvanized sheet, including its features, applications, manufacturing process, and advantages. By exploring these aspects, readers will gain insights into the benefits and potential uses of this material in various industries.

1. Features of Black Punched Galvanized Sheet

Black punched galvanized sheet possesses several distinctive features that make it a popular choice in construction and manufacturing sectors. Firstly, its galvanized coating provides excellent corrosion resistance, ensuring the longevity and durability of the sheet. Secondly, the punched surface enhances its aesthetic appeal while also increasing friction and grip. Lastly, the black color adds a unique and modern touch to architectural and design projects.

The black color is achieved through various methods such as powder coating or chemical treatments, which provide a uniform and consistent finish. Additionally, the punched pattern on the surface offers both visual interest and practical benefits, promoting air circulation and drainage.

2. Applications of Black Punched Galvanized Sheet

The versatility of black punched galvanized sheet makes it suitable for a wide range of applications. In the construction industry, it can be used for wall cladding, fencing, roofing, and decorative purposes. Its corrosion resistance and aesthetic appeal make it particularly suitable for outdoor structures.

In the manufacturing sector, black punched galvanized sheet finds applications in the production of appliances, automotive parts, and machinery components. The punched pattern can be customized to meet specific design requirements, providing functional and attractive solutions.

3. Manufacturing Process of Black Punched Galvanized Sheet

Black punched galvanized sheet is typically manufactured through a series of processes. First, the base material, usually steel or iron, is cleaned and pickled to remove impurities. It then undergoes a hot-dip galvanizing process, where it is dipped into a bath of molten zinc, forming a protective coating on its surface.

The next step involves creating the black punched finish. This can be achieved through powder coating, where a fine powder is electrostatically applied to the sheet and then cured under heat, resulting in a durable and attractive black finish. Alternatively, chemical treatments can be used to produce the black color, offering different shades and textures.

4. Advantages of Black Punched Galvanized Sheet

Black punched galvanized sheet offers numerous advantages that contribute to its popularity. Firstly, its galvanized coating provides exceptional corrosion resistance, ensuring a longer lifespan compared to non-galvanized materials. Secondly, the punched surface improves grip and traction, making it suitable for flooring and walkway applications.

Furthermore, the black color gives black punched galvanized sheet a contemporary and sophisticated appearance, making it highly sought-after in architectural and design projects. Its ability to withstand harsh outdoor conditions and its low maintenance requirements make it a cost-effective choice for long-term use.

Conclusion:

Black punched galvanized sheet is a versatile and durable material with a range of applications across various industries. Its unique features, including corrosion resistance, punched surface, and black color, make it an attractive option for both aesthetic and functional purposes. By understanding its features, applications, manufacturing process, and advantages, readers can appreciate the versatility and potential benefits of utilizing black punched galvanized sheet. Further research and exploration in this area can  uncover additional possibilities for this versatile material.

uncover additional possibilities for this versatile material.

Leave a Comment