Is it effective to deburr galvanized sheets

introduction

Abstract:

Is it effective to deburr galvanized sheets? This article aims to explore the effectiveness of deburring galvanized sheets. It provides background information on galvanized sheets and the importance of deburring for various industries. The article discusses four main aspects: the necessity of deburring, different deburring methods, considerations for deburring galvanized sheets, and the impact of deburring on the performance of galvanized sheets.

1. The Necessity of Deburring

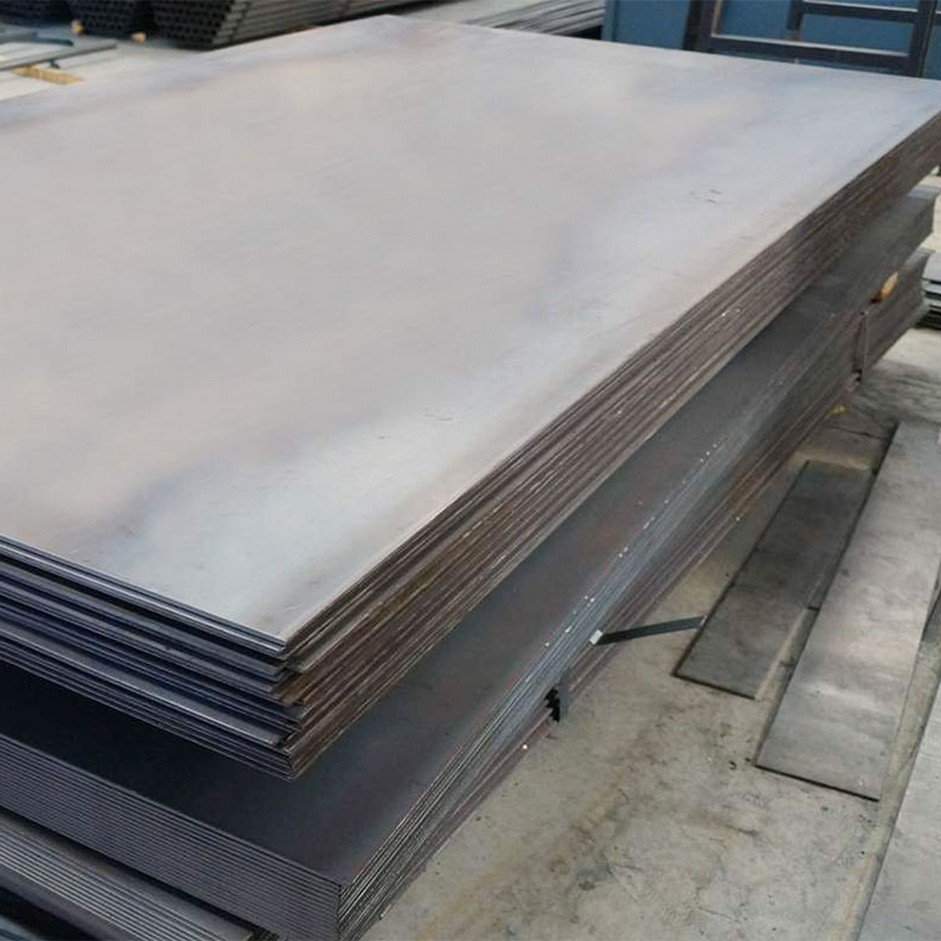

Galvanized sheets are widely used in industries such as construction, automotive, and manufacturing. However, during the galvanizing process, burrs may form on the edges or surfaces. These burrs can cause numerous issues, including reduced  functionality, compromised aesthetics, and potential safety hazards. Therefore, deburring is necessary to ensure the quality and performance of galvanized sheets.

functionality, compromised aesthetics, and potential safety hazards. Therefore, deburring is necessary to ensure the quality and performance of galvanized sheets.

It is important to note that the severity of burrs on galvanized sheets may vary depending on the manufacturing process and the intended use of the sheets. In some cases, the burrs may be minimal and do not require extensive deburring. However, in situations where burrs are prominent, it becomes imperative to implement effective deburring techniques.

There are several factors that determine the necessity of deburring, such as the end-use application, the cost implications, and the desired quality standards. It is essential for manufacturers to assess these factors and make informed decisions regarding the need for deburring.

2. Different Deburring Methods

Deburring galvanized sheets can be accomplished through various methods, each with its advantages and limitations. One common method is mechanical deburring, which involves the use of tools like grinders, brushes, and files to remove burrs. Mechanical deburring is efficient and suitable for large-scale production. However, it may not be ideal for intricate or delicate surfaces.

Chemical deburring is another popular method that utilizes chemical solutions to dissolve or soften the burrs. This method is effective for complex shapes and hard-to-reach areas. However, it requires careful handling of the chemicals and proper disposal protocols.

In addition to mechanical and chemical methods, thermal deburring involves using high temperatures to burn off the burrs. This method is particularly useful for removing burrs in hard-to-access areas. It is important to consider the material composition and thickness of galvanized sheets when selecting the appropriate deburring method.

3. Considerations for Deburring Galvanized Sheets

When deburring galvanized sheets, several considerations should be taken into account to ensure the best results. Firstly, it is crucial to choose the appropriate deburring method based on factors such as the severity of burrs, the desired finish, and the efficiency of the process.

Furthermore, care must be taken to avoid damaging the zinc coating on galvanized sheets during the deburring process. The zinc coating provides corrosion resistance, and any damage to it can compromise the overall performance and lifespan of the sheets. Proper techniques, tools, and expertise should be employed to prevent damage to the zinc coating.

Additionally, safety measures should be followed when deburring galvanized sheets. Some deburring methods may produce sharp metal particles or emit fumes, which can be hazardous. Protective equipment should be worn, and proper ventilation should be ensured in the deburring area.

4. Impact of Deburring on Performance

Deburring galvanized sheets can significantly impact their performance and functionality. By removing burrs, the sheets become smoother, reducing the risk of abrasion and friction-related damage. This, in turn, improves the overall efficiency and lifespan of the sheets.

Furthermore, deburring can enhance the appearance of galvanized sheets, making them more visually appealing and professional. For industries such as automotive and architecture, where aesthetics play a crucial role, deburring is essential to maintain high-quality standards.

Additionally, deburring can eliminate potential safety hazards caused by sharp burrs. In industries where galvanized sheets are handled or assembled, the presence of burrs can pose a risk to workers and end-users. By effectively deburring the sheets, these risks can be minimized.

Conclusion

In conclusion, deburring galvanized sheets is essential for ensuring their effectiveness and quality. The severity of burrs, the desired finish, and the industry requirements should be considered when selecting the deburring method. Care should be taken to avoid damaging the zinc coating during the process, and safety measures should be followed. By effectively deburring galvanized sheets, their performance, aesthetics, and safety can be significantly improved, making them suitable for various applications.

Future research could focus on developing more advanced and efficient deburring techniques specifically tailored for galvanized sheets, considering the evolving needs and requirements of industries relying on these materials.

Leave a Comment