Galvanized iron box

introduction

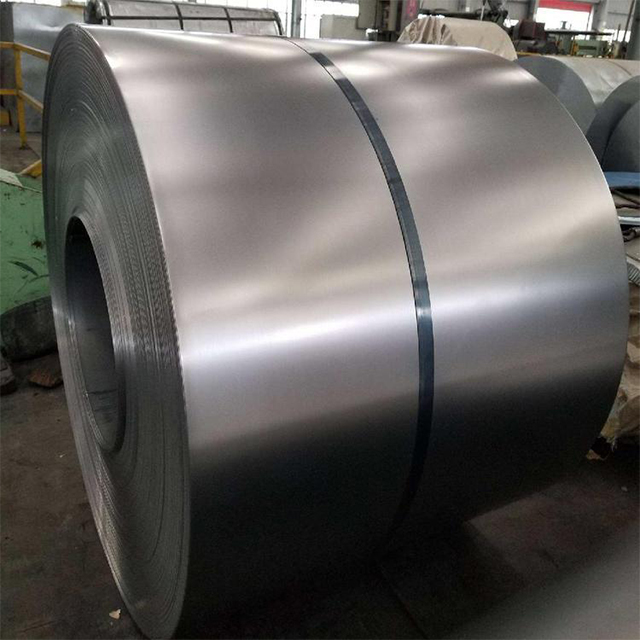

Galvanized Iron Box: A Comprehensive Exploration

Abstract:

In this article, we delve into the fascinating world of galvanized iron  boxes. With its unique properties and versatile applications, the galvanized iron box has become an integral part of various industries. Through this article, we aim to provide readers with a comprehensive understanding of galvanized iron boxes, including their history, manufacturing process, applications, and environmental impact.

boxes. With its unique properties and versatile applications, the galvanized iron box has become an integral part of various industries. Through this article, we aim to provide readers with a comprehensive understanding of galvanized iron boxes, including their history, manufacturing process, applications, and environmental impact.

1. History of Galvanized Iron Boxes

The origins of galvanized iron boxes can be traced back to the 17th century when the process of galvanization was discovered. This technique involves coating iron or steel with a layer of zinc, providing a protective barrier against corrosion. The galvanized iron box quickly gained popularity due to its durability and resistance to rust. We explore the advancements in galvanization technology throughout history and its impact on the development of galvanized iron boxes.

2. Manufacturing Process of Galvanized Iron Boxes

In this section, we delve into the intricate details of the manufacturing process of galvanized iron boxes. The process begins with the cleaning and preparation of the iron or steel surface, followed by the application of a zinc coating through hot-dip galvanization or electroplating. We discuss the advantages and limitations of each method, highlighting the importance of quality control during the manufacturing process. Furthermore, we explore the recent advancements in galvanization technology and their impact on the production of galvanized iron boxes.

3. Applications of Galvanized Iron Boxes

Galvanized iron boxes find widespread applications in various industries due to their unique characteristics. In this section, we explore the diverse range of applications, including construction, transportation, agriculture, and storage. We delve into the specific uses of galvanized iron boxes, such as in the construction of durable structures, transportation of goods, and storage of perishable items. Additionally, we discuss the benefits of galvanized iron boxes in terms of cost-effectiveness and environmental sustainability.

4. Environmental Impact of Galvanized Iron Boxes

As with any industrial process, it is essential to assess the environmental impact of galvanized iron boxes. In this section, we evaluate the environmental consequences associated with the manufacturing, usage, and disposal of galvanized iron boxes. We discuss the measures taken by industries to mitigate these impacts, such as implementing recycling programs and adopting sustainable manufacturing practices. Furthermore, we explore alternative materials and technologies that could potentially reduce the environmental footprint of galvanized iron boxes.

Conclusion:

In conclusion, galvanized iron boxes have played a pivotal role in various industries due to their durability, corrosion resistance, and versatility. Through this article, we have provided a comprehensive overview, covering the history, manufacturing process, applications, and environmental impact of galvanized iron boxes. It is evident that galvanized iron boxes continue to be an invaluable asset in numerous sectors, contributing to their efficiency and longevity. However, it is crucial to remain vigilant about the environmental implications and strive towards sustainable practices in their production and usage. Further research and development in this field will undoubtedly enhance the future of galvanized iron boxes and pave the way for a more sustainable and resilient industry.

Leave a Comment