Galvanized steel coil quality

introduction

Galvanized Steel Coil Quality: Ensuring Excellence in the Manufacturing Process

Abstract:

The article aims to explore the importance of galvanized steel coil quality, providing readers with a comprehensive understanding of this crucial aspect. This includes an overview of galvanized steel coils, their manufacturing process, and the significance of maintaining high-quality standards. By shedding light on various factors affecting quality, this article aims to emphasize the significance of ensuring excellence in every stage of production.

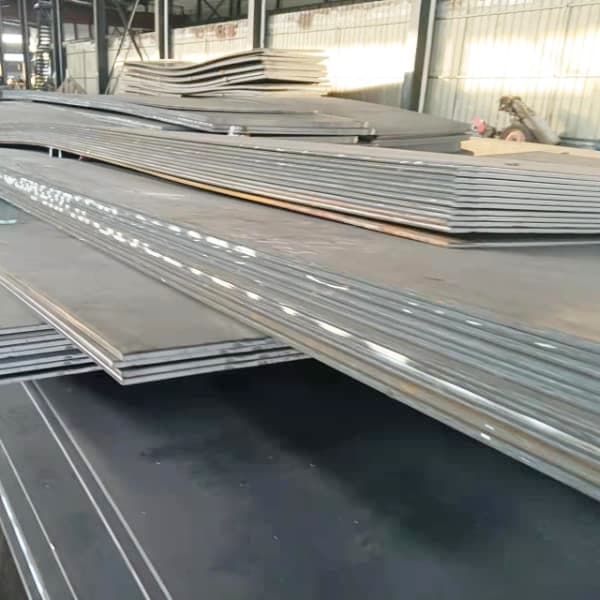

1. Understanding Galvanized Steel Coils

Galvanized steel coils are steel products coated with zinc to enhance their corrosion resistance and overall durability. This section will delve into the composition, properties, and uses of galvanized steel coils. We will also touch upon the historical background and the growing demand for this versatile material.

2. Factors Affecting Galvanized Steel Coil Quality

2.1 Raw Materials Selection

The quality of galvanized steel coils heavily relies on the choice of raw materials. We will discuss the different types of steel used in coil production and how their attributes impact the final product. Factors such as carbon content, impurity levels, and tensile strength will be covered in detail.

2.2 Manufacturing Process

The manufacturing process plays a vital role in determining galvanized steel coil quality. This section will explore essential steps such as cleaning, pickling, annealing, galvanization, and cooling. We will highlight the significance of each stage in ensuring optimal quality and discuss potential challenges that manufacturers may face.

2.3 Coating Thickness and Uniformity

The thickness and uniformity of the zinc coating greatly impact the performance and lifespan of galvanized steel coils. Here, we will elaborate on the methods used to measure coating thickness, such as magnetic and eddy current techniques. Additionally, we will explore the importance of maintaining uniform coating distribution throughout the entire coil surface.

2.4 Quality Control Measures

To maintain consistent quality, strict quality control measures must be implemented throughout the manufacturing process. This section will highlight various quality control techniques, including visual inspections, mechanical testing, and chemical analysis. We will discuss the significance of these measures in identifying any defects or deviations from the desired specifications.

3. Importance of Galvanized Steel Coil Quality

3.1 Performance and Durability

High-quality galvanized steel coils offer superior performance and durability, making them suitable for a wide range of applications. We will delve into the impact of quality on factors such as corrosion resistance, mechanical strength, and formability. Additionally, we will explore how subpar quality can lead to premature failure and increased maintenance costs.

3.2 Safety Considerations

Galvanized steel coils find application in industries that require robust and reliable materials. This section will focus on safety considerations, discussing the repercussions of using low-quality coils in critical infrastructure, such as automotive, construction, and electrical sectors. We will emphasize the importance of stringent quality standards in safeguarding public safety.

3.3 Economic Implications

Inefficient production processes, substandard raw materials, and low-quality galvanized steel coils can have significant economic repercussions. This section will examine the economic impact of quality issues, including increased wastage, decreased productivity, and potential legal liabilities. By showcasing the financial advantages of investing in high-quality products, we will underline the long-term benefits for manufacturers and end-users.

4.  Conclusion

Conclusion

In conclusion, galvanized steel coil quality is a fundamental aspect of the manufacturing process that deserves meticulous attention. Through this article, we have explored various factors that contribute to the overall quality of galvanized steel coils, including raw material selection, the manufacturing process, coating thickness, and quality control measures. We have also highlighted the importance of maintaining high-quality standards in ensuring superior performance, safety, and economic viability. By prioritizing galvanized steel coil quality, manufacturers can enhance their reputation, attract loyal customers, and contribute to the development of a sustainable future for the industry.

Leave a Comment